Introduction

The world of 3D printing is about to become a lot more exciting. In 2025, Bambu Lab, a well-known name in consumer 3D printing, may bring a revolutionary upgrade: compatibility with metal filaments.

This would make metal 3D printing accessible to a much broader audience, from hobbyists to small businesses.

For the first time, people could create metal parts at home with just a 3D printer and a spool of metal filament. Thanks to a new partnership between Bambu Lab and Virtual Foundry (TVF), this exciting possibility is closer than ever.

| Preview | Product | Rating | Price | |

|---|---|---|---|---|

| eSUN Silk Metal PLA Filament 1.75mm, Silky Metallic 3D Printer Filament PLA, Dimensional Accuracy… |

$23.99 | Buy on Amazon |

A Game-Changing Collaboration

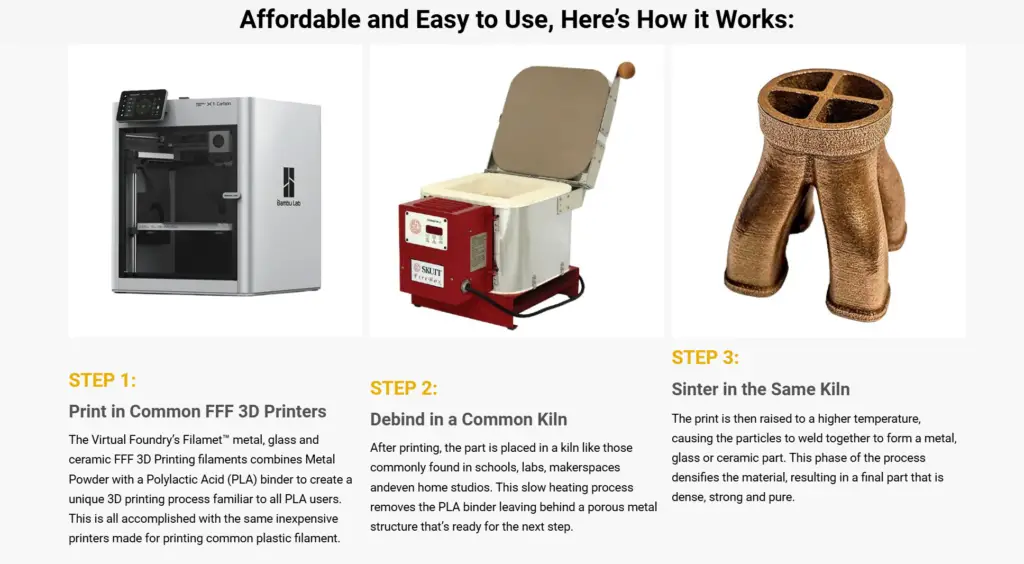

On December 20, 2024, Virtual Foundry, a leader in metal 3D printing filaments, announced a key distribution agreement with Bambu Lab. This collaboration combines TVF’s Filamet™ metal filaments with Bambu Lab’s user-friendly FDM 3D printers, offering a powerful solution for metal printing.

Why This Matters for Metal 3D Printing

The partnership aims to simplify and democratize metal 3D printing. Until now, creating metal parts has typically required expensive equipment and specialized knowledge. However, with the Filamet™ filaments, users can print metal just like they would with regular plastic filaments.

After printing, a simple post-processing step—debinding and sintering—will transform the print into a solid metal part. This makes metal 3D printing more accessible to a range of users, including hobbyists, engineers, and small businesses.

TVF offers a wide variety of metal filament options, including stainless steel, copper, aluminum, and titanium, all of which are compatible with Bambu Lab’s 3D printers.

These printers are known for their affordability and practicality, making them a perfect fit for users looking to experiment with metal printing without breaking the bank.

Key Benefits of This Partnership

| Feature | Description |

|---|---|

| Affordability | Metal 3D printing, once reserved for large businesses due to high costs, is now accessible to hobbyists and small businesses. This partnership makes it possible by pairing Bambu Lab’s affordable printers with TVF’s reasonably priced filaments. |

| Ease of Use | No special knowledge is required to use the metal filaments with an FDM printer. This simplicity allows anyone familiar with 3D printing to switch to metal printing with minimal effort. |

| Wide Range of Applications | Metal filaments unlock new possibilities for creators across industries, whether you’re prototyping for engineering, creating custom tools, or designing artistic projects. |

| Comprehensive Support | Both Bambu Lab and TVF offer guidance and resources to help users achieve the best results with their metal prints. |

The Changing Landscape of Metal 3D Printing

For years, companies like Desktop Metal and Markforged have been the go-to names in metal 3D printing, but their solutions come with hefty price tags. This has opened up opportunities for new players like TVF and Bambu Lab, whose focus on affordability and ease of use is changing the game.

Emerging players like BCN3D and Raise3D are also entering the metal printing market, often partnering with material suppliers like BASF.

However, with the recent bankruptcy of BASF’s Forward AM division, TVF has found an opportunity to fill the gap, offering high-quality materials and solutions that make metal 3D printing more accessible than ever.

The Future of Metal 3D Printing: A New Era

This partnership between TVF and Bambu Lab could mark the beginning of a new era for metal 3D printing. In the coming years, we may see metal printing become an everyday tool for creators, hobbyists, and businesses alike.

This could reduce production costs, speed up prototyping, and enable highly customizable manufacturing at home or in small workshops.

The ability to print metal parts with an affordable 3D printer could also lead to new innovations in low-volume manufacturing. Small businesses could design and produce custom metal parts on demand, bypassing the need for expensive tooling and large production runs.

This is just the beginning of what promises to be an exciting and transformative journey.

Conclusion

The collaboration between Bambu Lab and Virtual Foundry represents a huge step toward making metal 3D printing accessible to the masses. By combining affordable printers with versatile metal filaments, this partnership opens up new possibilities for hobbyists, engineers, and small businesses alike.

If successful, it could help position Bambu Lab as one of the leading providers of metal 3D printing solutions, bringing innovation and cost-effective production to a whole new audience.

As we look to the future, it’s clear that metal 3D printing is poised to become more than just a tool for large-scale manufacturers—it’s about to become an essential part of everyday creation.

The barriers to entry are lower than ever, and with Bambu Lab and Virtual Foundry leading the charge, this technology will soon be within reach for anyone with a passion for making.

FAQ

Q1: What types of metal filaments are best for beginners?

A1: Stainless steel and bronze are often recommended for beginners due to their balance of printability, strength, and ease of use. These metals are versatile and can be used for a wide variety of applications.

Q2: How can I maintain my 3D printer when using metal filaments?

A2: It’s important to clean your printer regularly, especially the nozzle, as metal filaments can cause more wear than plastic. Using a hardened steel nozzle will help protect against this. Regular maintenance ensures smooth prints and longevity of your printer.

Q3: Do I need special equipment to sinter metal parts after printing?

A3: Yes, sintering requires a special oven that can reach high temperatures to remove the binder and solidify the metal. However, this process is straightforward, and many hobbyists use commercially available sintering ovens designed for 3D printed parts.

Leave a Reply