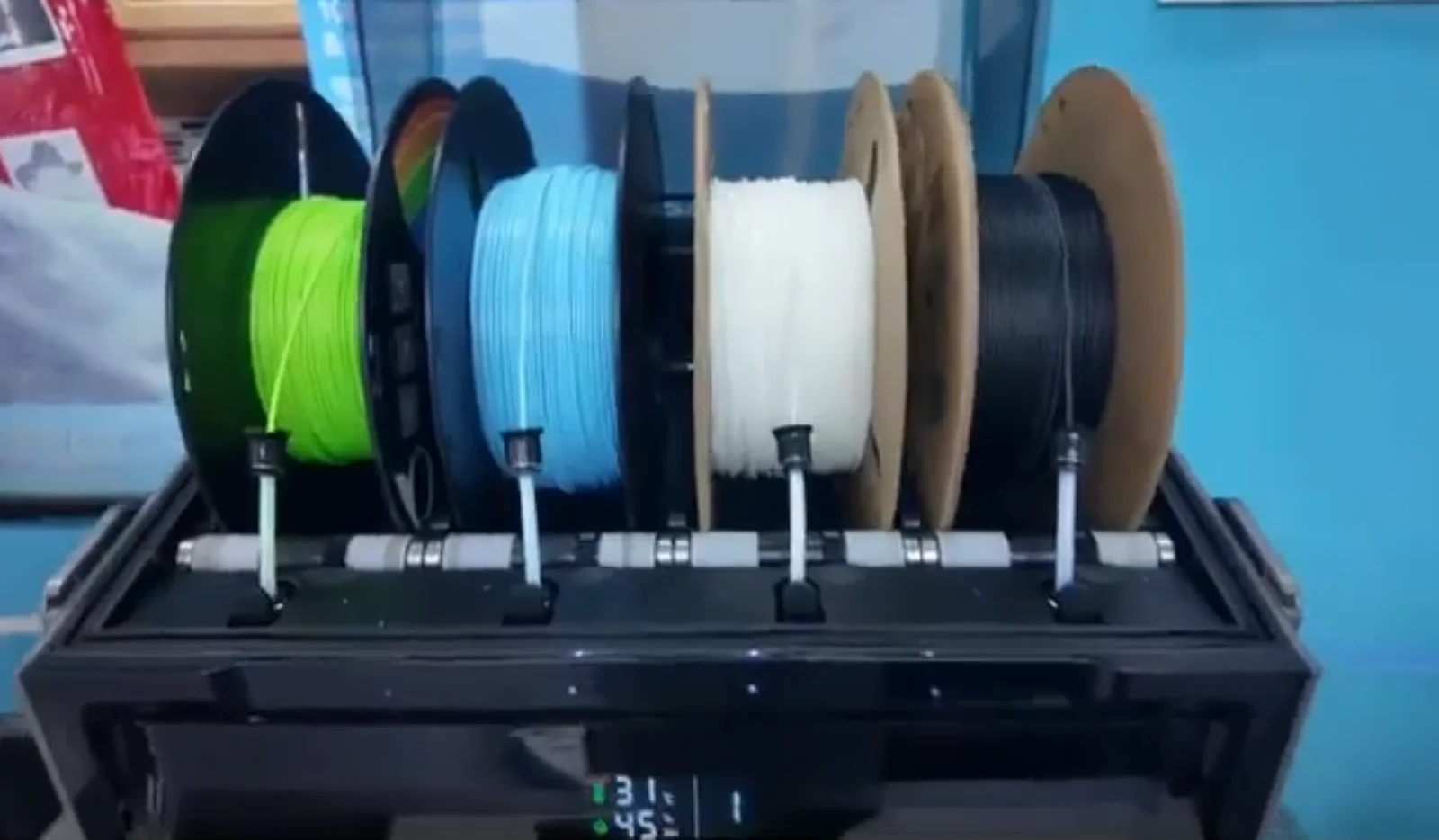

Filament jams are a common but manageable challenge for K2 Plus users. Tackling this issue promptly not only keeps your projects on track but also helps maintain your printer’s long-term performance.

In this guide, we’ll walk through the necessary steps to troubleshoot and resolve filament jams efficiently. With just a few basic tools and a bit of patience, you can restore smooth filament flow and keep printing without interruption.

Tools You’ll Need

Before you start, gather these essential tools:

- Hex wrench for loosening extruder screws

- Needle to clear filament pathways

- Heat source (the printer’s nozzle preheating function or a heat gun)

Step 1: Access the Extruder’s Interior

The first step is to carefully remove the outer shell of the extruder. This provides access to the filament path and allows you to assess where the clog is located.

- Remove the screws: Using a hex wrench, unscrew the three screws securing the extruder shell.

- Release the compression block: Press the compression block until the extruder gear disengages from the drive mechanism. This allows for easier access to the inner components.

- Detach the shell: Carefully lift off the extruder shell to expose the filament path.

Note

Pay attention to the internal spring in the extruder assembly. Ensure it stays in place, which will make reassembly easier.

Step 2: Clearing the Clog

With the extruder open, check where the filament is jammed. Choose one of the following methods based on the filament’s visibility in the pathway.

Method One: Visible Filament Head

If you can see the filament head inside the pipe, use this method to clear the clog:

- Heat the nozzle to the extrusion temperature. This softens the filament, making it easier to remove.

- Remove the deformed filament: Using cutting pliers, gently grip and pull the softened filament out. Use caution to avoid breaking it within the path.

- Reassemble the extruder: Once the filament is cleared, reassemble the extruder shell, screws, and compression block as it was initially.

This method should restore smooth filament flow. However, if you cannot see the filament head, try Method Two.

Method Two: No Visible Filament Head

If the filament head is not visible, try this alternative approach:

- Heat the nozzle to the extrusion temperature. This helps soften any jammed filament deep in the pipe.

- Heat the tip of a needle: Warming the needle allows it to reach and soften the jammed material within the pathway.

- Insert the needle and allow it to cool: Insert the heated needle into the filament path and wait about 30 seconds. This cooling process causes the filament to adhere to the needle.

- Slowly remove the needle: Carefully pull the needle out to bring the jammed filament with it.

- Reassemble the extruder: Once the blockage is cleared, replace the extruder shell, secure the screws, and ensure the spring is correctly positioned.

Final Check: Testing the Filament Flow

After reassembly, test the filament flow by running an extrusion test at normal printing temperature. This final step confirms that the filament pathway is clear and that your printer is ready for reliable printing.

Tips for Preventing Future Filament Jams

Keeping your K2 Plus printer in peak condition is easier with a few simple maintenance habits:

- Regularly clean the nozzle to prevent residue buildup.

- Use high-quality filament suited to your printer to avoid material inconsistencies that can cause jams.

- Unload filament if the printer is unused for long periods to prevent clogs from filament degradation.

By taking these preventive steps, you’ll be less likely to experience filament jams and can enjoy consistent, high-quality prints. Encountering a filament jam might be frustrating, but following these steps will have you back to printing smoothly in no time!

Leave a Reply